The accuracy of a thermometer is a fundamental attribute that determines its reliability and usefulness. Accuracy refers to how closely the thermometer’s measurements align with the true or actual temperature being measured.

When selecting a thermometer, it is important to consider its accuracy specifications and ensure that it meets your specific requirements.

Thermometers are labeled with an accuracy rating or margin of error, representing the maximum deviation of the displayed temperature from the actual temperature. For instance, the InstaProbe meat thermometer boasts exceptional accuracy of ±0.5°F (±0.3°C) from -4 to 248°F (-20 to 120°C), with ±1.8°F (±1.0°C) otherwise.

Instant Read Meat Thermometer

How do you know if your thermometer is accurate?

Is your thermometer trustworthy?

It is important to perform periodic checks on your thermometer, especially when it is new, after any mishandling or impact, during prolonged periods of non-use, and whenever doubts arise about its reliability.

Test its accuracy yourself (Ice Bath Test & Boiling Water Test)

To verify the accuracy of the thermometer by yourself, it is recommended to test it in both boiling water and an ice bath.

Boiling temperatures can vary significantly based on elevation, unlike the ice point which remains consistent. To ensure accurate results, it is recommended to determine the boiling point specific to your location before conducting the boiling water test on your thermometer.

Way 1. Ice Bath Test

Step 1. Fill a cup or container with ice, ensuring it reaches the brim. Preferably crushed ice to minimize gaps.

Step 2. Add cold water until it reaches approximately 1/2 inch below the ice level. Ensure the ice remains submerged without floating. Adjust the water level if needed.

Step 3. Immerse the thermometer probe in the water, making sure it doesn’t touch the container’s bottom or walls. Stir the ice bath for at least one minute, allowing the thermometer needle to stabilize.

Step 4. Check the thermometer’s calibration by verifying the reading at 32°F (0°C). Compare it to the manufacturer’s specified accuracy range (look for the ±°F in the instrument’s documentation). If it falls within the specified tolerance, no adjustment is necessary.

Way 2. Boiling Water Test

Step 1. Ensure you have a pot of water ready. Bring the pot of water to a rolling boil on the stove.

Step 2. Insert the probe of the thermometer into the boiling water, making sure it goes at least an inch deep. Avoid touching the sides or bottom of the pot.

Step 3. Allow the thermometer to register the temperature, takes less than 0.5s if you are testing Typhur InstaProbe.

Step 4. Check the thermometer reading. It is considered accurate if it registers 212°F (100°C), which is the boiling point of water at sea level.

Compare it to an established standard (NIST)

This method involves comparing the thermometer’s readings to a reference thermometer that is known to be accurate. The National Institute of Standards and Technology (NIST) provides certified traceable thermometers with precise measurements. You can compare your thermometer’s readings to the readings of the NIST-certified thermometer at different temperatures to assess its accuracy.

InstaProbe prioritizes temperature reading accuracy, designing devices to meet NIST standards. Calibrated against an SPRT 4386 in a stirred liquid bath at 7 temperatures with 7.5 cm immersion depth, the results are ±0.5°F (±0.3°C) from -4 to 248°F (-20 to 120°C); otherwise ±1.8°F (±1.0°C).

Thermometers like InstaProbe that are certified in such a way receive what is called a “NIST-traceable” calibration certificate and are known to be accurate.

Traceability is characterized by several essential elements, including:

- Reference to a Known Standard: Traceability involves the ability to trace a measurement or calibration result back to a known and recognized standard (such as NIST).

- Chain of Comparisons: Traceability requires a documented and auditable chain of comparisons between the instrument being calibrated and the known standard. Each step in the chain of comparisons should be properly documented, indicating the measurement or calibration procedure used and the instruments or standards involved at each stage.

- Measurement Uncertainty: Traceability requires consideration of measurement uncertainty. It involves quantifying the uncertainties associated with the measurements and calibrations, taking into account factors such as instrument repeatability, reproducibility, and the uncertainties associated with the calibration standards and procedures.

- Documentation and Records: This includes documenting the calibration procedures, measurement results, and any adjustments or corrections made during the calibration process.

What affects the accuracy of thermometers?

1. Calibration points

The calibration points play a significant role in determining the accuracy of a thermometer.

Do you know why?

According to ASTM E230 standard, the error limit for a Class I, Type K thermocouple is ±1.5℃, and the temperature-error relationship may be difficult to maintain consistently over a wide temperature range. To ensure temperature measurement accuracy, it is necessary to select an adequate number of calibration points over a large range to obtain more calibration data, allowing the program to validate and verify the calibration results.

As we mentioned before, InstaProbe was calibrated in a calibration bath at 7 temperatures, meaning InstaProbe used 7 calibration points compared to most instant thermometers on the market that use 2-5 calibration points.

By using more calibration points, InstaProbe can have a more comprehensive understanding and evaluation of the performance characteristics of the thermocouple, thereby providing more accurate and reliable temperature measurement results in practical applications. This calibration method helps reduce errors caused by temperature variations and improves the overall performance of the temperature-measuring instrument.

| Temperature range | -4-248°F (-20-120℃) | Otherwise |

| Accuracy spec | <=±0.5°F (±0.3°C) | ±1.8°F (±1.0°C) |

When selecting temperature measurement equipment, considering the number and coverage of calibration points can significantly enhance the accuracy and reliability of temperature measurement.

Thermometer speed

The accuracy of temperature measurement and the response speed of a thermometer can be considered as a trade-off.

To achieve high accuracy, a thermometer needs to be given enough time to reach thermal equilibrium with the object or environment being measured. This allows the sensor to stabilize and provide an accurate reading.

On the other hand, faster response times may come at the cost of slightly reduced accuracy, as the thermometer may not have enough time to fully equilibrate with the new temperature.

To achieve both high accuracy and fast response speed, InstaProbe has implemented optimizations in both software and hardware:

- Software algorithms optimization that optimizes temperature measurement. These algorithms effectively suppress measurement noise and environmental disturbances, enhancing temperature stability. This ensures that temperature readings are precise and reliable. Simultaneously, the algorithms are designed to maintain a quick response time, striking the optimal balance between accuracy and speed.

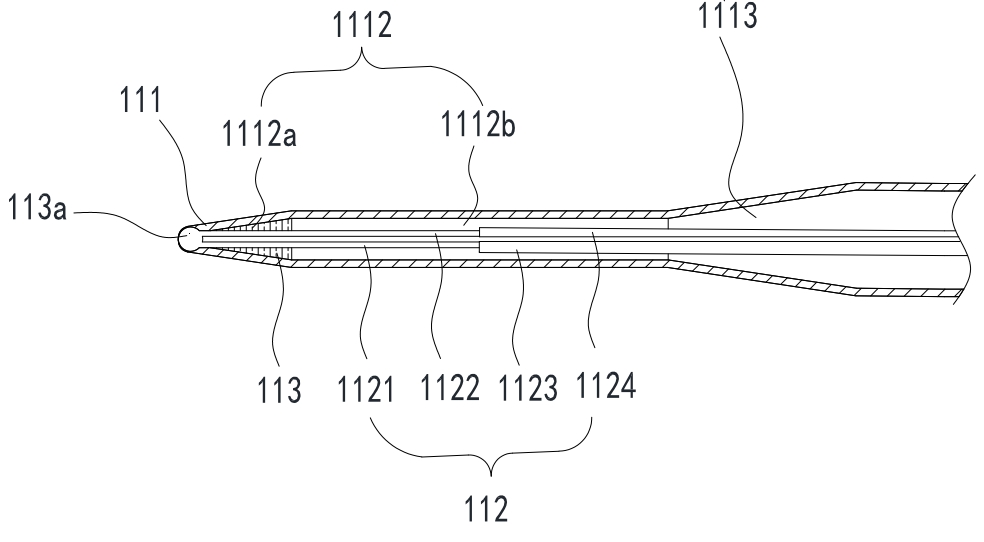

- InstaProbe utilizes Direct Contact Thermocouple Integration (DCTI) technology. This involves directly integrating the thermocouple with the needle tip, allowing for direct contact with the heat source. This DCTI technology enables more accurate and responsive temperature measurements. This direct integration minimizes any potential thermal lag or delays in temperature detection, resulting in faster response times.

As a result, the InstaProbe meat thermometer reaches 0.5s full reading time with ±0.5℉ (±0.3°C) accuracy.

Hardware materials quality

The quality of raw materials used in manufacturing thermometers, as well as the manufacturing processes themselves, can have a significant impact on the accuracy and reliability of the instruments.

Thermocouple

The selection of thermocouples can impact the accuracy of temperature measurements made by a thermometer. Two common types of thermocouples are Type K and Type J. Type K thermocouples are suitable for a wide temperature range from -328°F to +2,498°F (-200°C to +1370°C), while Type J thermocouples are suitable for a lower temperature range from -40°F to +1382°F (-40°C to +750°C).

InstaProbe specifically utilizes Type K thermocouples, allowing for accurate temperature measurements within a broad temperature range while mitigating the risk of premature accuracy drift due to thermal shocks.

This selection enhances the reliability and performance of the InstaProbe thermometer, ensuring consistent and accurate readings even when subjected to extreme temperature variations.

Thermocouple wiring

Thermocouples typically consist of two different metal wires, known as the positive and negative leads. To minimize interference in the circuit, it is important to isolate the thermocouple from other wires as much as possible.

Additionally, to avoid introducing temperature errors, the cold end of the thermocouple should maintain a stable temperature. The cold end can be connected to a stable temperature reference point, such as a cold junction compensation circuit or a cold reference ground. In the case of InstaProbe, a high-precision NTC (Negative Temperature Coefficient) sensor is used to accurately measure the cold end temperature.

Power supply design

Power supply design also plays a crucial role in temperature measurement. The InstaProbe project utilizes a dedicated voltage reference chip, which enables a voltage reference accuracy of 0.5%. This accuracy determines the precision of temperature acquisition.

Conclusion

In conclusion, the accuracy of thermometers is crucial for reliable temperature measurements in various applications.

However, since thermometers indirectly measure temperature through various mechanisms, ensuring their accuracy relies on rigorous standards and calibrations. We are dependent on this intricate system to validate the accuracy of our instruments. By recognizing the significance of accurate temperature measurement and embracing reliable calibration practices, we can confidently rely on our thermometers for precise temperature monitoring and control in diverse settings.