In the ever-evolving world of temperature measurement, precision and efficiency are paramount. Enter DCTi™, or Direct Contact Thermocouple Integration, technology. This cutting-edge innovation is transforming the way we collect temperature data.

In this article, we’ll delve into the depths of DCTi technology, exploring its intricacies and discovering how it significantly impacts reading speed.

What is DCTi technology?

DCTi™ (Direct Contact Thermocouple Integration) is a technology that involves directly touching the heat source with a thermocouple probe.

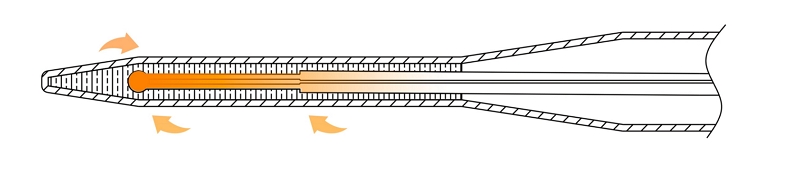

In most common thermocouple probes available in the market, consist of a stainless steel tube, and the thermocouple’s sensing tip is inserted into the tube’s end. Usually, before inserting the thermocouple, heat-conductive silicone grease is applied to the probe’s tip. In this type of probe, the heat from an external source travels through the stainless steel tube wall, then through the heat-conductive silicone grease, and finally reaches the thermocouple sensing tip.

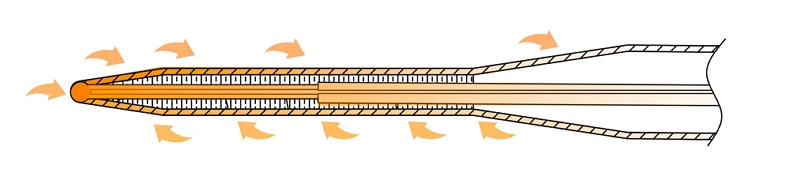

The DCTi™ technology used in Typhur InstaProbe instant read thermometer, on the other hand, places the temperature-sensing thermocouple directly at the tip of the tube, allowing the thermocouple to make direct contact with the external heat source being measured. This design eliminates the need for the heat energy from the source to pass through the stainless steel tube wall and heat-conductive silicone grease. As a result, it significantly boosts the speed at which the probe can measure temperature.

How DCTi technology affects reading speed?

From the explanation of DCTi™ above, it’s clear that the main goal of this technology is to speed up the temperature detection process of probes. By allowing the thermocouple sensor to directly touch the heat source being measured, it achieves the fastest possible temperature measurement in theory.

When we dive deeper into the design of the Typhur InstaProbe’s probe, we can see that the thermocouple sensor has a part outside the probe tip, which can make direct contact with the heat source, and another part inside the probe.

This setup can lead to a situation where, during temperature measurement, if the inside of the probe hasn’t reached the same temperature as the heat source being measured, heat can still transfer through the thermocouple sensor into the probe’s interior. This prevents the thermocouple from quickly reaching a thermally stable state.

To ensure that the interior of the probe reaches a thermally stable state as quickly as possible, injecting heat-conductive silicone grease at the tip of the probe is a solution.

Heat-conductive silicone grease is a material with excellent heat conductivity, typically composed of silicone gel and heat-conductive fillers. It serves the dual purpose of filling gaps and efficiently conducting heat, helping the probe’s tip reach thermal stability rapidly. This also means that using a heat-conductive grease with better thermal conductivity can result in even faster temperature measurements by the probe.